Log Ladders

Maximized throughput, zero wasted cycles. Optimized control for log infeed.

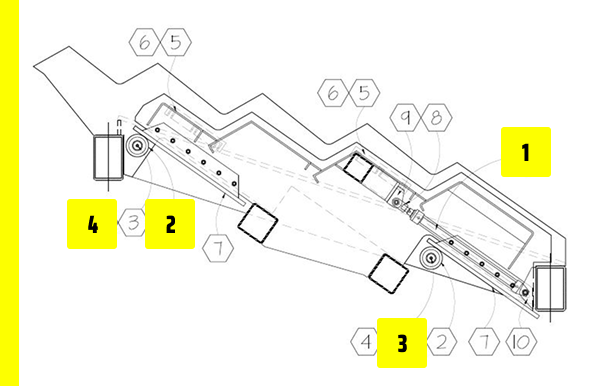

Linden Log Ladders are designed to move logs up and forward efficiently—ensuring there’s always a log ready for delivery to the next step. Each ladder step is powered by a torque pipe and lift arms, actuated either by hydraulic cylinders or electric drive (motor + reducer). Steps operate independently, eliminating empty cycles and reducing log gaps in your flow.

One Step Ahead, Every Time.

Torque Pipe & Lift Arms

Deliver synchronized lifting action to move logs upward

1

Independent Step Activation

Prevents log gaps and empty cycles

2

Hydraulic or Electric Drive

Configurable to suit site power preferences

3

Customizable Step Geometry

Built to match log sizes and mill layout

4

Key Benefits:

- Independent step actuation – Eliminates empty cycles

- Precision flow control – Ensures every log is ready for transfer

- Flexible power options – Available in electric or hydraulic configurations

- Custom-built – Match your log lengths, elevation, and line requirements

- Ideal for elevation gain – gain height without compromising flow

- Reliable operation – Rugged design for mill-duty performance

Specifications:

- Log Length: 8’ to 24’

- Log Diameter: Up to ~30”

- Cycle Rate: ~15 CPM

- Actuation: Hydraulic cylinders

- Add-on: Tempo follower cylinder for precision control

- Feed Type: Log Singulation

Applications:

Linden Log Ladders are ideal for systems where elevation gain, flow control, and log spacing are essential. Use them to:

- Elevate logs from deck to infeed

- Maintain consistent flow without bunching or gaps

- Feed systems such as lathe chargers, merchandisers

- Handle short, long, or uneven logs with confidence

Documentation & Manuals

For over 50 years, Linden Fabricating has been a trusted partner in the forestry industry. Today, we go beyond singulation equipment – we design integrated systems that keep your mill running smoothly.