Linden’s Log Sorting Systems are engineered to scan, separate, and distribute logs efficiently — improving flow to processing lines while maximizing yard inventory control. Designed for rugged mill environments and custom-built to meet the unique needs of each operation, these systems support high-speed sorting, log optimization, and seamless integration with Linden feeders, saws, and handling equipment.

Smarter Processes. Proven Designs.

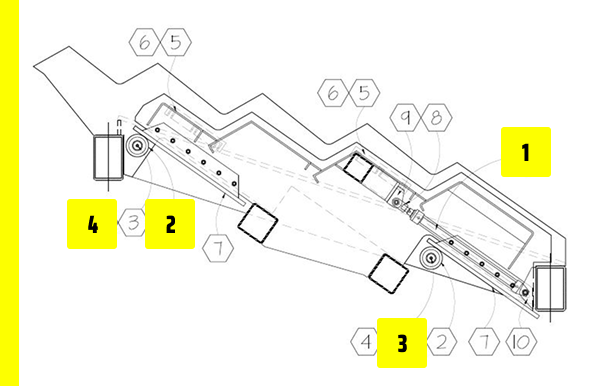

Automated Kickers / Diverters

Sort logs by length, diameter or grade

1

Integrated Infeed & Outfeed

Smooth transitions between decks and bins

2

Custom Bin Configurations

Designed to match yard layout and production goals

3

Key Benefits:

- Increased Throughput

High-speed sorters keep up with modern mill production rates. - Improved Inventory Control

Sort by size, grade, or species for better production planning. - Flexible System Design

Every system is engineered to your facility’s layout and volume demands. - Durability Built In

Designed for heavy logs, harsh weather, and around-the-clock use. - Seamless Integration

Works in tandem with Linden feeders, saws, conveyors, and control systems. - Custom Automation Options

Integrates with sensors, PLCs, and optimization software for smarter sorting.

Applications:

- Primary log breakdown areas requiring classification before processing

- Log yards needing consistent staging and supply to mill infeed systems

- Merchandiser saw lines feeding specific lengths into different production paths

- Operations optimizing for value recovery by sorting by diameter, species, or quality

- Green-end systems requiring scalable, high-throughput automation

Specifications:

- Log Length: 20’ to 70’

- Log Diameter: 4” to 30”

- Self-Cleaning Design: Integrated full-face step

- Actuation: Hydraulic driven torque tube

Documentation & Manuals

For over 50 years, Linden Fabricating has been a trusted partner in the forestry industry. Today, we go beyond singulation equipment – we design integrated systems that keep your mill running smoothly.